Good is not good enough. It needs to be perfect for you!

How Mitschke Kunststoffwerk helps you to improve the quality of your plastic parts while simultaneously saving costs…

Particularly highly complex plastic systems often call for the manufacturing necessity of following the injection molding with other production processes. Mitschke Kunststoffwerk provides you with 5000m² of production space with highly efficient multi-purpose systems for manufacturing whole assembly groups with third-party parts. Additionally, you thus gain improvements in the durability and the look of your plastic parts. It is thereby insignificant whether we are dealing with small batch sizes or high volume production. Our quality management during production is, of course, certified according to ISO 9001:2015.

Increase your profitability by streamlining your procurement process. The complete assembly of Mitschke Kunststoffwerk enables you to draw all your plastic parts from one source. This means that you can integrate your plastic parts directly and without delays into your production process. Moreover, you can keep an eye on costs at all times since all manufacturing processes necessary for your project are already included in the unit price.

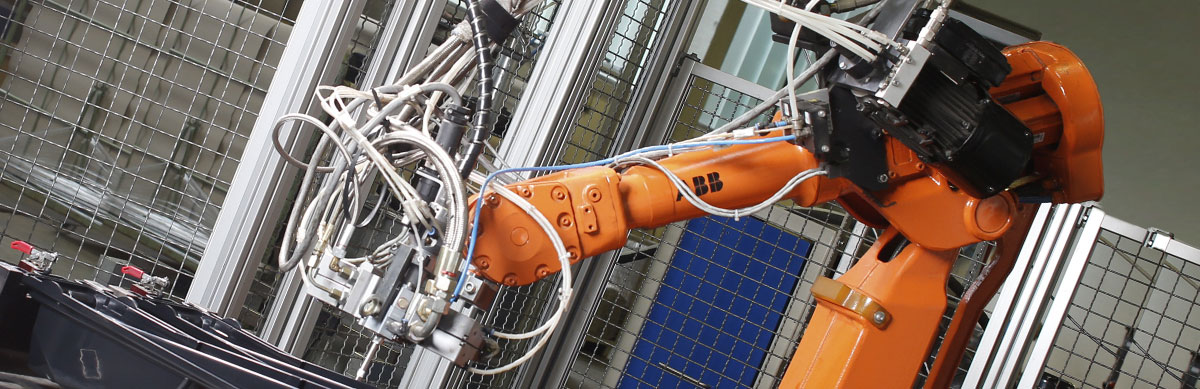

Foaming and ultrasonic welding in one step

Pure efficiency!

Does your plastic part require the integration of different thermoplastic materials, compounds, fleeces, fibers, or films? In these cases, Mitschke Kunststoffwerk employs a multifunctional, efficient robot: it not only realizes three-dimensional welds, but also applies a two-component sealing foam on the work piece at the same time. You profit from visually perfect, strong weld seams as well as continuous welding quality and fast running times. Ultrasonic welding is a clean technique. Chemical additives and adhesives are unnecessary. Therefore, homogeneous recycling of welded work pieces is possible. Ultrasonic welding only uses a fraction of the energy needed for other thermal welding processes – to the benefit of our environment.

Hot-tool welding

Joining complicated forms? Nothing could be easier…

…if you know how it’s done. Naturally, the comprehensively trained employees of Mitschke Kunststoffwerk are skilled in mastering all parameters that need to be applied in this important joining technology process. This provides an excellent way to join complicated, three-dimensional product geometries and different kinds of plastic.

Milling and stamping

Optimal cost-benefit-ratio…

In case of small lot sizes, an individual tool insert is not always profitable. Especially with very tight tolerances, milling and stamping are particularly suitable for the production of part alternatives – realized cost-efficiently, fast, and in perfect quality in your Mitschke Kunststoffwerk.

Imprinting

Spare yourself a trip…

With our pad printing machinery, we are able to apply 极乐 wherever you wish them to be on your thermoplastic plastic part. Naturally, we can also imprint other symbols, e.g. serial numbers or your logo – whatever you like!